Laser cutting is a metalworking process. It is available for sheets from 0.5 mm to 12 mm (aluminum) or up to 25 mm (steel) thickness. The size of the sheet metal is up to 1.5 x 3 m. The workpieces are cut from the sheet by a focused laser beam. In addition, a process gas (nitrogen or oxygen) is used, which protects the optics and blows the molten material out of the kerf. Most steels use oxygen as the process gas. An oxide layer is created on the cut edges, which has to be removed for some subsequent steps. In the case of stainless steels, galvanized steels and aluminum, nitrogen is used to blow out the kerf. The cut edge then does not oxidize. The price for a workpiece is made up of a share for the cutting time (depending on the material, thickness, cutting length, number of grooves), the material price and the fixed costs. If there are several identical workpieces, the fixed costs are only incurred once, i.e. the price per workpiece decreases considerably, depending on the geometry.

Laser inscriptions are created by tracing contours with a low beam power. A tarnish engraving is formed through oxidation of the metallic surface: a colored, mostly brown, layer. This technology can be used to make markings for further processing steps in your own workshop, such as punch marks or assembly marks, as well as lettering or identification of the parts. Laser engravings are waterproof, smudge-proof and permanent, but there are no recessed structures, so they cannot be felt.

Production examples

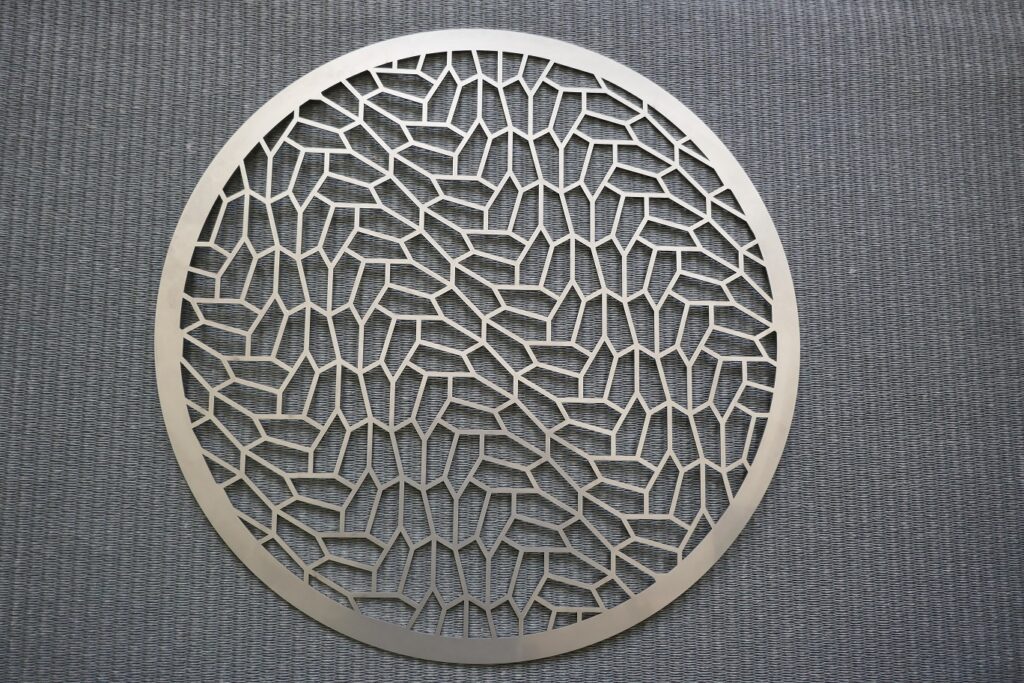

Stainless Steel 12 mm Disc

Aluminum lever

Grill grate Stainless 2 mm

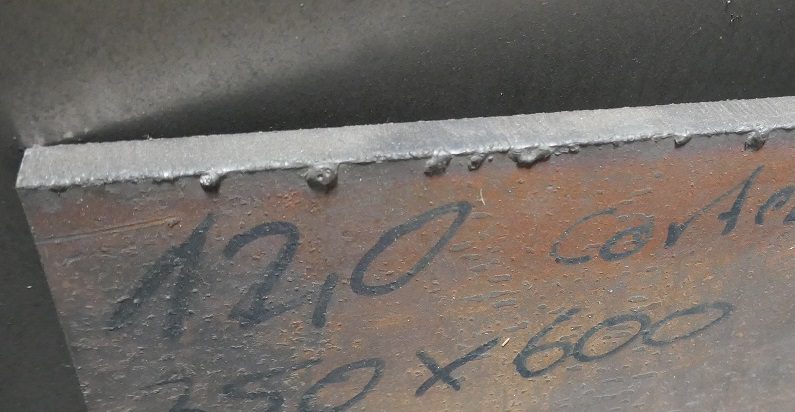

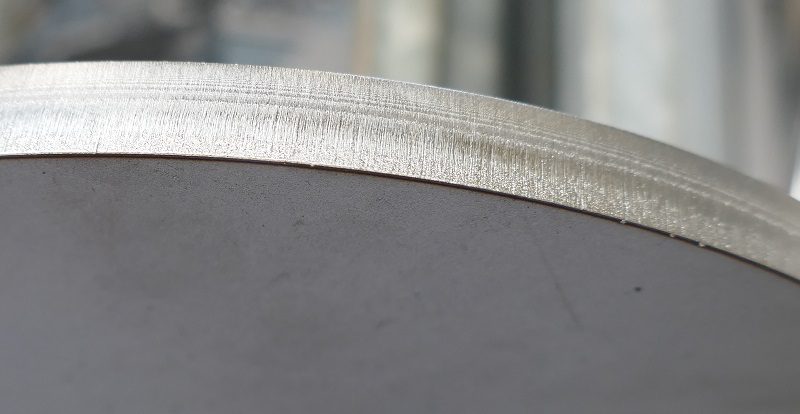

The formation of burrs and roughness of the cut edges increase with the sheet thickness, see the following pictures of the non-reworked edges. From a thickness of 2.0 mm, the cut parts are deburred by us in order to avoid injuries on sharp edges.

Images of the cut edges and laser inscriptions

Cut edge Stainless 5 mm

Cut edge Aluminum 12 mm

Cut edge Steel 12 mm

Cut edge Stainless steel 12 mm

Procedure

Create a new workpiece, select “laser cutting” as the method, the material and the thickness.

You draw the workpiece in the teknow Designer. White lines indicate the outer contour or openings. Yellow lines are interpreted as engraving lines. You can use the wizard to check that all design rules have been followed. The price for a single workpiece will be displayed after you have closed the designer. We create a production file from your drawing. We manufacture according to DIN ISO 2768-m / EN ISO 9013-342.

Advantages of the procedure

• No tool costs

• Individual parts possible

• short production time

• High precision

• fine structures can be produced

• flexible geometry can be produced

• Parts can be labeled immediately

• Parts are free of burrs

Design rules

The smallest hole diameter must be at least equal to the selected material thickness, the smallest web width equal to twice the selected material thickness. Here, too, the wizard provides appropriate information (marked as a warning). If all rules are observed, the production takes place with tolerances according to DIN ISO 2768-m / EN ISO 9013-342.

The warnings can be ignored. As a rule, the results are acceptable (e.g. slightly smaller holes), but we cannot guarantee compliance with DIN ISO 2768-m / EN ISO 9013-342 at these points.

The metal sheets are mostly 300 x 150 cm², larger workpieces lead to an error message.

Materials

Aluminum

AlMg3 (3.3535): Standard aluminum alloy for medium loads. Can be edged and welded very well. Corrosion-resistant, even against sea water. To choose from the strengths 1.0; 1.5; 2.0; 2.5 3; 4; 5; 6; 8th; 10 and 12 mm.

Steel

DC01 (1.0330) is a thin sheet in the range 1.0 – 3.0 mm (from 4 mm S235JR), for general applications, cold-rolled and oiled.

To choose from the strengths 1.0; 1.5; 2.0; 2.5 and 3.0 mm.

S235JR (1.0038, ST 37-2) is an unalloyed, inexpensive standard structural steel for general applications. Rust protection is required outdoors. DC01 is used with a thickness of less than 4 mm.

To choose from in the strengths 4; 5; 6; 8th; 10; 12; 15; 18; 20 and 25 mm.

S355J2G3 (1.0570, ST 52-3) is an unalloyed, stronger standard structural steel for general applications. Very easy to weld. Rust protection is required outdoors.

To choose from the strengths 1.0; 1.5; 2.0; 2.5 3; 4; 5; 6; 8th; 10; 12; 15; 18; 20 and 25 mm.

DX51 (1.0226) is a sendzimir galvanized sheet steel, very easy to form, zinc coating approx. 275 g / m², layer thickness approx. 20 µm. Cut edges must be protected.

To choose from the strengths 1.0; 1.5; 2.0; 2.5 and 3.0 mm.

Stainless Steel

X5CrNi18-10 (1.4301, V2A) is the standard quality of chrome-nickel steels, easy to weld, easy to polish, very corrosion-resistant to environmental influences, except seawater.

To choose from the strengths 1.0; 1.5; 2.0; 2.5 3; 4; 5; 6; 8th; 10; 12; 15; 18 and 20 mm.

X6CrNiMoTi17-12-2 (1.4571, V4A) is a stainless steel with good strength at high temperatures, easy to weld, easy to polish, very corrosion-resistant to environmental influences, including seawater.

To choose from the strengths 1.0; 1.5; 2.0; 2.5 3; 4; 5; 6; 8th; 10; 12; 15; 18 and 20 mm.

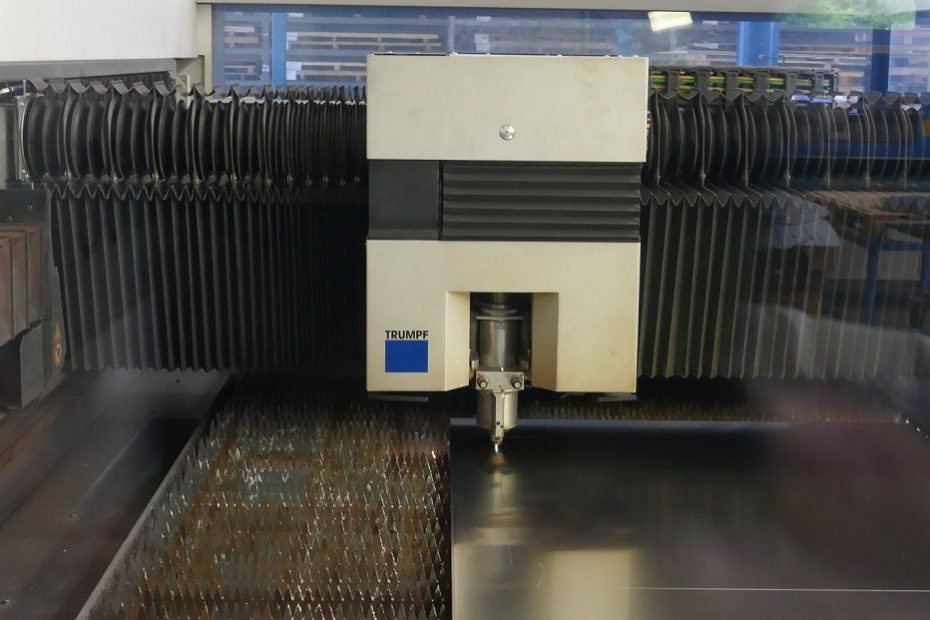

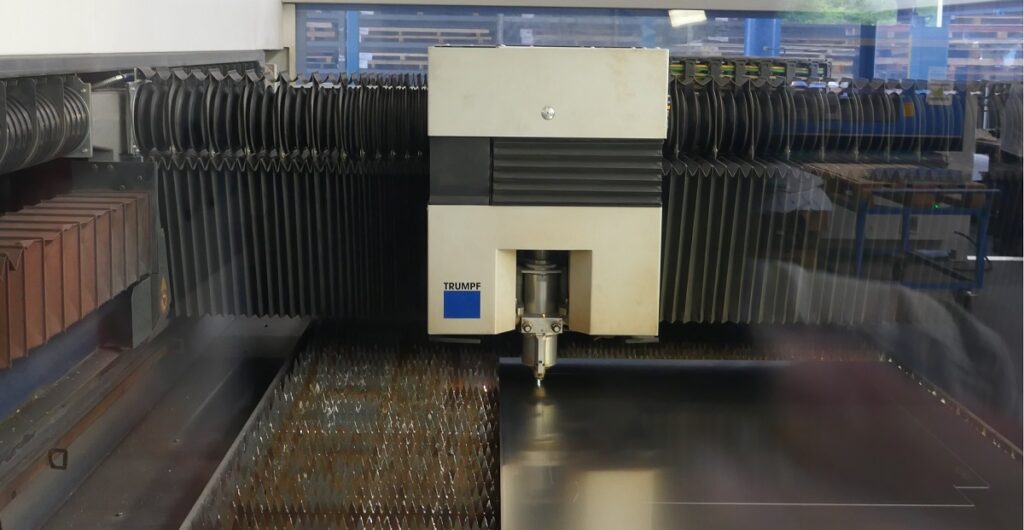

Finally a look into the production:

The sheet metal is cut with the laser cutting machine at the front left, the sheet metal store at the rear left, and the press brakes at the rear right.

The inside of the laser cutting machine: this is where the sheets are cut.