first Steps

This is how you produce a workpiece with teknow.

You have to think about the following things if you want to produce a workpiece with teknow – we give tips and hints.

In order to produce something on teknow, you have to create a so-called “workpiece” under “My teknow” and enter the information required for production there. Then you can create the drawing according to which your workpiece is to be manufactured or upload an existing drawing. In order for everything to go well, some preliminary considerations are necessary. Here is the guide. This videoshows you how to create a workpiece.

The requested information – production method, material and material thickness – is required to determine the appropriate production rules and the price.

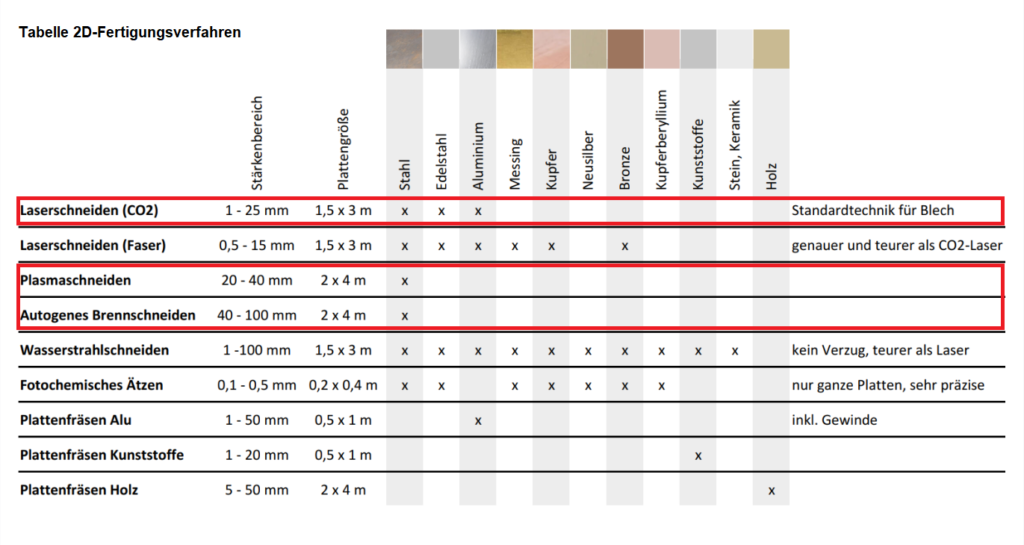

Which method do I use to process which materials?

Most of the time you will have an idea of the material you want to make something from: steel, aluminum, stainless steel (these are the “material groups”). Based on the material group, you can use the table to determine the suitable manufacturing process. Sometimes there are several manufacturing options for a material group. In some cases, the choice of manufacturing process also depends on the material thickness. You can change the manufacturing process, material and material thickness at any time until the order is placed.

Note: The manufacturing processes outlined in red are already available. The rest is following.

Material and material thickness

Once you have selected the manufacturing process and material group, the next step is to determine the material you want, and finally the material thickness. The material groups, such as stainless steel, contain different materials for different purposes. To make the selection easier, teknow automatically enters a standard material in the selection field that is suitable for most applications. In the case of stainless steel, for example, this is V2A (material number 1.4301). You can find a description of the materials here. We have listed possible areas of application and areas for which the material does not fit. For example, if your workpiece belongs to a boat and is in contact with salt water, the standard material V2A is not suitable, you then select V4A (1.4571) from the material selection. A brief summary of the properties of the selected material appears below the selection field.

The last step is to determine the material thickness. Different material thicknesses are available depending on the material. Sometimes the maximum workpiece size also depends on the selection – we provide a note under the selection field.

The drawing

Now you have to create a drawing for the workpiece you have created. You can do this in our drawing editor or by uploading a finished drawing file. Before you get started with the editor, you should watch these videos. You can find more information about the drawing program and the ordering process under Help.

When you have finished your drawing, you can use the teknow wizard to check whether all the details are producible. Using the manufacturing rules that match the manufacturing method, material and material thickness, the wizard marks the areas that cannot be machined (for example, holes that are too small in relation to the material thickness) or that are critical, for example could melt during laser cutting. The wizard provides information on how the points can be remedied, partly also through automatic procedures (such as “Set hole to minimum size”).

You can import your own files from other CAD systems into teknow in dwg or dxf format. There are a few rules here that must be observed. A correct setting of the export function (for example “no splines”) can avoid considerable loss of quality. You can find instructions in the FAQs.

Order

As soon as you have a drawing that is ready for production, teknow can show you the price. To do this, you close the CAD editor. The price for various quantities and the weight of an individual part appear on the workpiece view. You can change the method, material and thickness, teknow calculates the new price – unless your workpiece can no longer be produced with the new settings. Then you have to adapt the drawing.

So that your workpiece is actually manufactured, you have to initiate an order. To do this, select “Add to shopping cart” on the finished workpiece. You can then store your data in the shopping cart and check the price and shipping costs before you submit your order. We produce and deliver your parts, usually within 10 days.