Order your laser cuts online!

Laser cuts made to measure – completely free design of outer contours and cutouts

Precise laser cuts according to your own specifications and completely individually? At teknow you can configure yourself and order your laser cuts online.

What can a laser cut?

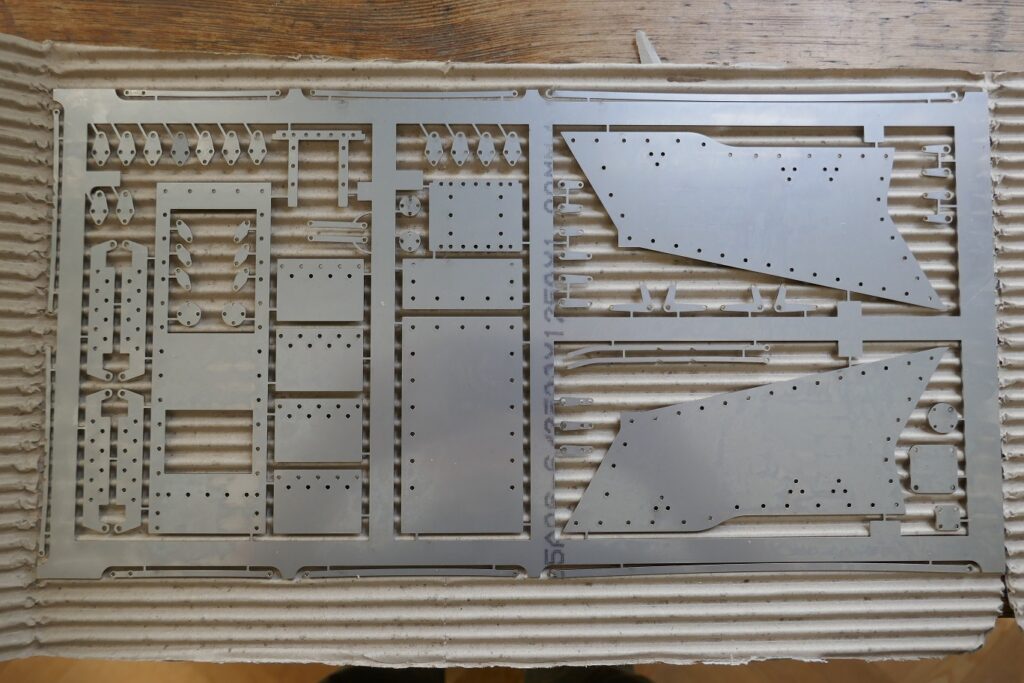

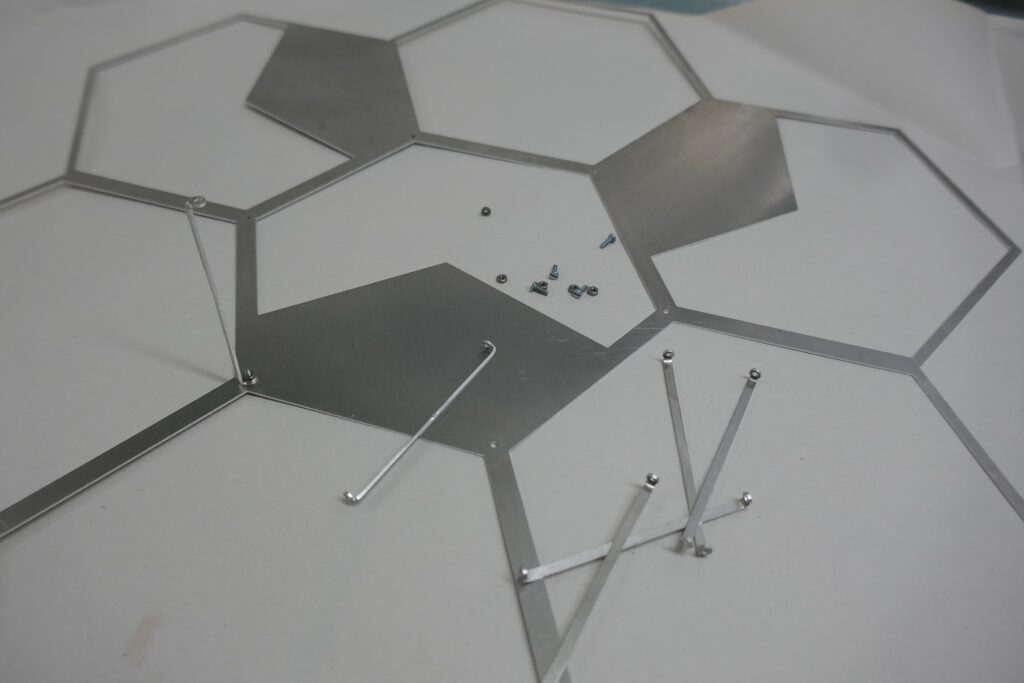

With laser cutting, particularly precise workpieces can be cut into shape from a wide variety of materials. At teknow we use steel, aluminum and stainless steel, all of which are perfectly suited for laser processing. The workpieces are cut from the board by a focused laser beam. As a manufacturing process, it is therefore ideally suited to producing individual cuts.

Brass

Stainless Steel

Aluminum

Steel

What are the advantages of laser cutting?

The concentrated laser beam used to make your cuts guarantees a high level of accuracy – fine structures and geometric patterns are easy to produce. By using a laser, there are no additional tool costs – and your customized laser cut is ready for shipping after a very short production time.

Laser cutting at teknow – What do I have to pay attention to?

So that you can hold your individual project in your hands at the end, teknow has a very special approach. When you start designing your workpiece, you first choose your manufacturing method, i.e. laser cutting, and then your material group. We automatically fill in a standard material that you can easily use if you don’t have any specific requirements. After you have chosen your desired material thickness, you can move on to drawing.

In our CAD drawing editor you can start with some basic shapes or your own drawing. Once your drawing is finished, you can have it checked and repaired if necessary. If it can be produced as planned, it will turn green in the CAD editor – your go!

Of course, you can also upload your own DWG/DXF files – our CAD wizard also works with them.

How to:

This video explains the production process in detail step by step.

The price of your designed workpiece depends on the current material costs and the complexity of your workpiece. As soon as your workpiece is ready for production, you will be shown the price for your order. After you have submitted the order, you can expect your new, tailor-made laser cut in the next 10 days.